Domestic Construction Licenses

| Type | Registration No. | Date |

|---|---|---|

| Civil engineering and construction |

No. 1229 | 92.12.04 |

| Civil engineering | No. 1229 | 92.12.04 |

| Construction | No. 1229 | 92.12.04 |

| Industrial and environmental facility |

Industrial Facility 13-0001 | 99.03.10 |

| Landscape architecture | Landscaping-13-0001 | 99.03.10 |

| Facility Maintenance | Chungnam Boryeong 2000-29-01 | 00.04.20 |

| Gas facility Class 1 | 98-27-1-1 | 98.05.22 |

| Professional fire-fighting facility |

Gyeonggi Hwaseong No. 2008-27 | 00.09.06 |

| Electric work | Chungnam-00130 | 98.06.20 |

| ICT construction | No. 112382 | 02.03.06 |

| Real estimate development | Gyeonggi 080272 | 08.06.04 |

| Soil purification | No. 2007-01 | 07.01.12 |

| Engineering (quality test) | No. E-9-2481 | 06.09.28 |

| Housing construction | Gyeonggi –Housing and Land 2004-0035 | 04.03.22 |

| Building(facility) management |

No. 3138102806 | 06.09.28 |

| Petroleum sales (gas station) |

Gyeongnam Haman No. 78 | 15.09.15 |

Overseas Construction Licenses

| Type | Registration No. | Date |

|---|---|---|

| Engineering construction-Civil engineering and construction |

No. 525 | 06.03.17 |

| Engineering construction-Landscape architecture | No. 110 | 06.03.17 |

| Engineering construction-Landscape architecture | No. 72 | 06.03.17 |

| Gas facilities | No. 24 | 06.03.17 |

| Electric works | No. 495 | 06.03.17 |

| Professional environmental construction | No. 42 | 06.03.17 |

| ICT construction | No. 203 | 06.03.17 |

Combustible waste,

sorted and produced

into unshaped SRF

Combustible waste, sorted by a separator, is dried by natural energy as pre-treatment. Then, soil and impurities within the combustible waste are removed by a hitting-type crusher

-

In particular, wind generated from this process is used for the second drying before a rotary-type dryer is employed. Re-utilization of the crusher reduces energy significantly and contributes to mass-production of high-quality solid fuel (unshaped SRF). Our innovative, environmentally-friendly technology of turning waste into renewable energy, has been applied to Busan Myeongji and Incheon Chongna construction sites.

Weight reduction and recycling facilities

Definition of SRF

Regular SRF

(Solid Refuse Fuel)

SRF made out of domestic waste, waste synthetic resins, waste synthetic fabrics, waste rubber, and waste tires, other than the designated waste defined by the Waste Management Act, Article 2, and Subparagraph 4 (Act on the Promotion of Saving and Recycling of Resources, Enforcement Rules, Attachment 1, Subparagraph 10)

Certificate

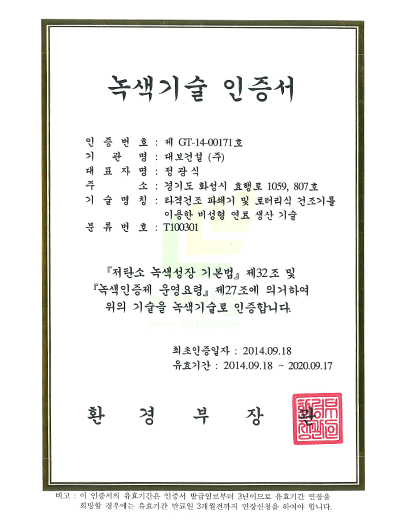

Green Technology Certification(No. GT-14-00171)

Certificate

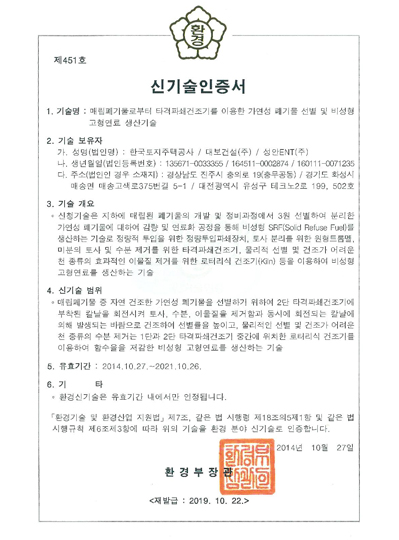

New Environmental Technology Certification(No. 451)

Biomass Solid Refuse Fuel

SRF made out of waste paper, agricultural waste, waste wood, vegetable residue, herbaceous plants, etc. (Act on the Promotion of Saving and Recycling of Resources, Enforcement Rules, Attachment 1, Subparagraph 10)

01Selection of

On-site

combustible waste

(incineration)02Recyclable

On-site

combustible waste03Intermediate

Recycling service

processing of waste

(Cement furnace )SRF

Recycling service

(Special boiler)

Result and Benefits

Significant contribution to national policy objectives

-

From mere 'waste treatment' to 'sales of resources', we have considerably contributed to one of the nation's policy objectives, namely, effective 'waste recycling'. When applied to national projects such as the insanitary landfill maintenance project and agricultural waste plastic recycling project, the technology can result in significant economic and environmental benefist

Reduction in environmental pollution

-

· Utilization of waste for energy, replacing fossil fuel and reducing greenhouse gases

· Recycling of waste soil, which is usually incinerated or buried in landfill

· Minimization of waste to be incinerated or buried, which can extend the life of a landfill

Head reinforcement of

steel pipe piles with

circular fastening plate

(no welding and no bolts)

Environmentally friendly method of head reinforcement of steel pipe piles, using a circular fastening plate (no welding and no bolts).

-

Lightweight disk-type upper/lower fasteners are coupled with L-shaped rebar via the hole of the upper steel pipe pile, and the following results are expected:

-

1

Structural stability secured by conveying top load deep to the foundation

-

2

No need for welding and no bolts secures safety of workers and reduces CO2 welding waste and noise

-

3

Use of factory-fabricated circular fastening plate reduces on-site work and installation time

-

4

Construction cost minimized by use of equipment

-

5

Use of parts with little price fluctuation to stabilize construction cost

-

1

-

This environmentally friendly technology has been recognized for its superiority and applied to various construction sites of the Korea Expressway Corporation, Korea Rail Network Authority, and local governments in order to reduce construction period, costs, and environmental pollution

Head reinforcement of steel pipe piles

-

1

-

2

-

3

-

4

- Piling

- Step 1 Head preparation

- Step 2 Hammering for

steel pipe piles - Step 3 Installation of

concrete end-panel - Circular fastening plate

(no welding and no bolts) - Step 4 Installation of main bar

- Step 5 Installation of tie bar

- Placing of concrete

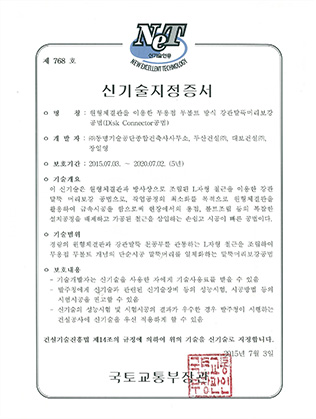

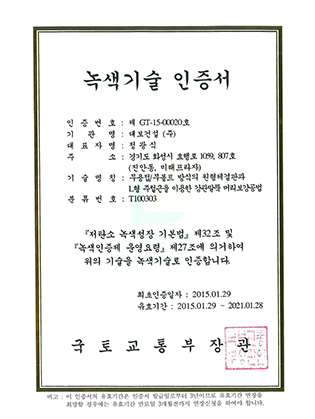

Certificate

Certificate

Certificate

Together with unrivalled technology and extensive experience,

our expertise in construction has been widely recognized